Week 15: Sintering joining Processes

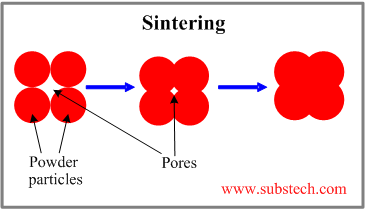

Sintering

Sintering is a manufacturing process in which a fine powder that has been formed into a shape is subsequently fired at temperature below melting point. The compact, when fired, densifies and becomes non-porous . The powder particles form bonds at this temperatures and the contact points between particles, which were originally formed under the mechanical pressure during compaction, increase in size and strength, improving

mechanical properties. sintering is a thermal treatment that densification accompanies it. Densification almost always requires shrinkage. The shrinkage takes place as a result of materials being transported by one or more of several diffusion processes. This may involve a liquid or reactive liquid or diffusion at grain boundaries or through the volume of particle