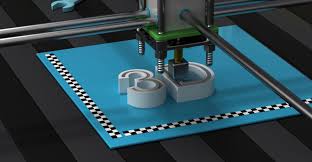

Week 16: Additive Manufacturing: 3D printing

3D Machining

In contrast to traditional subtractive manufacturing techniques like milling or turning or formative processes like casting or forging, additive processes shape the part by adding material. This is mostly done lay er by layer, even if the layer itself is composed of discrete volumes. The basic steps involved in the process are as below.

1. Create a CAD model of the design

2. Convert the CAD model to STL format

3. Slice the STL file into thin cross-sectional layers

4. Construct the model one layer atop another

5. Clean and finish the model

According to Kruth [7], the material addition processes may be divided by the state of the manufacturing

material before part formation.

1. Liquid-based processes

2. Powder-based processes

3. Solid-based processes