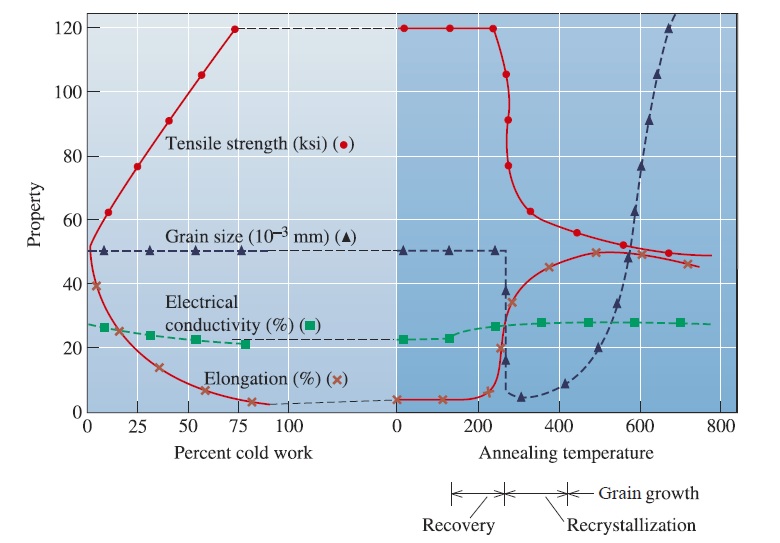

Week 6; Lecture 11 to 12,Annealing effect of imperfection on the mechanical properties of materials

A small portion of the applied stress is stored in the form of residual stresses within the structure as a tangled network of dislocations. The presence of dislocations increases the total internal energy of the structure. As the extent of cold working increases, the level of total internal energy of the material increases. Residual stresses generated by cold working may not always be desirable and can be relieved by a heat treatment known as a stress-relief anneal. The residual stresses are not uniform throughout the deformed metallic material. For example, high compressive residual stresses may be present at the surface of a rolled plate and high tensile stresses may be stored in the center. Annealing is a heat treatment used to eliminate some or all of the effects of cold working. Annealing at a low temperature may be used to eliminate the residual stresses produced during cold working without affecting the mechanical properties of the finished part, or annealing may be used to completely eliminate the strain hardening achieved during cold working. In this case, the final part is soft and ductile but still has a good surface finish and dimensional accuracy. After annealing, additional cold work can be done since the ductility is restored; by combining repeated cycles of cold working and annealing, large total deformations may be achieved.