Week 5; Lecture 9 and 10, Elastic and plastic deformation.

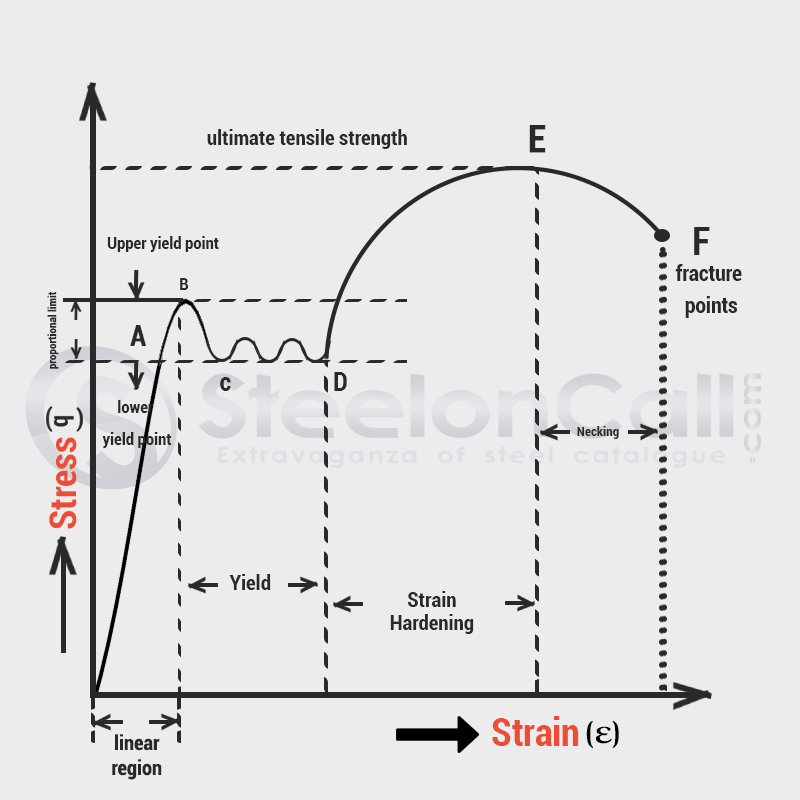

In many of today’s emerging technologies, the primary emphasis is on the mechanical properties of the materials used. For example, in aircraft manufacturing, aluminum alloys or carbon reinforced composites used for aircraft components must be light weight, strong, and able to withstand cyclic mechanical loading for a long and predictable period of time. Steels used in the construction of structures such as buildings and bridges must have adequate strength so that these structures can be built without compromising safety. The plastics used for manufacturing pipes, valves, flooring, and the like also must have adequate mechanical strength. Materials such as pyrolytic graphite or cobalt chromium tungsten alloys, used for prosthetic heart valves, must not fail. Similarly, the performance of baseballs, cricket bats, tennis rackets, golf clubs, skis, and other sports equipment depends not only on the strength and weight of the materials used, but also on their ability to perform under “impact” loading. The importance of mechanical properties is easy to appreciate in many of these “load-bearing” applications.The stress-strain curve can be used to read off the structural loadability of materials. For many materials, including metals, their loading bearing capability (loadability) is one of the most important material properties. The loading capacity of metals is tested in a so-called tensile test. In this test a standardised metal bar is slowly pulled apart (stressed in tension) until the bar gives way under the load and breaks.

Ref. Donald R. Askeland